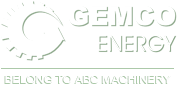

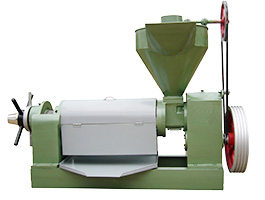

YZS-130A automatic oil press

- Capacity : 10T/24H

- Power : 18.5kW +1.5kw

- Weight : 1000kg

- Dimension : 2350*810*2000mm / 1350*700*570mm

Detail Introduction

This integrated oil expeller press is advaned model from common screw oil expllers, it is able to performing both cold and hot pressing with automatic temperature rising and oil-cleaning system. This model automatic oil press can also be applied for a great number of vegetable plant, it is good at expelling soybean, peanuts, sesame seed, sunflower seeds, rice bran, cottonseed and the like.

2. Cakes thickness reflects the pressure inside the chamber. Thicker cake indicates lower pressure inside the chamber, thinner cake-higher pressure inside. If raw material has less oil content, chamber pressure should be higher, cake will be thinner, round plates need to be tightenedt In the case of high oil content material, pressure in the chamber should be lower, then circular plates need to be loosened, resulting in thicker cake. Recommended thickness of cakes will be.

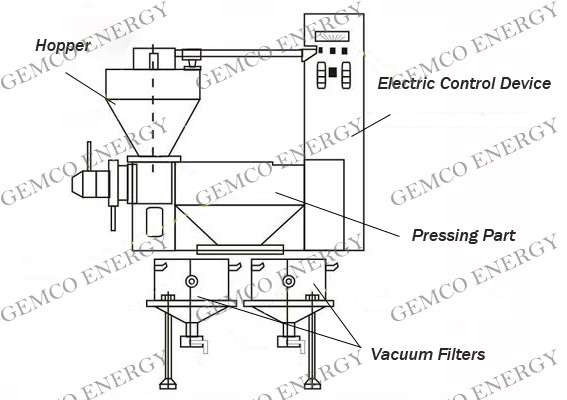

YZS-130A Automatic Oil Press Structure

The machine is mainly contains four parts: feeder, press chamber, electrical control carbinet and vacuum filters.- The heating system is inside press cage, heater help to heat the press case to get to the pressing temperature in short time and improve the oil output rate.

- The electric cabinet is used to control the pressing temperature automatically.

- The vacuum filters help to clarify the crude oil expelled and guaranteed the good oil quality.

YZS-130A Machine Features

- Cast iron machine base;

- Gear reducer system;

- Superior grade oil & cake;

- Compact structure, stable function, simple maintenance.

- Main parts through the processing of high-temperature tempering and low temperature quenching;

Factors Affecting Oil Output Rate

Water content is the critical factor, as a matter of fact, water content directly affects oil output rate. However, user usually has not proper inspection equipment. since water content of some main raw material may be detected as follows:- Bean: If teeth beating could crack it, forming flat pieces accompanied with light sound, the watercontent is suitable. Flat piece without cracking means too wet. Heating or sunshine may be drive water off! However, cracking accompanied with loud indicates too dry. Adequate water needs to be added.

- Cotton seeds: shell and kernel may be separated by teeth beating. Shell breaking may be accompanied by sound, which means water content is suitable. Shell being flatting indicates too wet, shell being splitted into powder means too dry

- Rape seeds: They can be pressed either at hot or at cold state. Cold pressing; extruding by finger, if they splitted into two pieces, accompanied by sound and oil, this implicates water content is adequate. Otherwise, extruding makes power indicates too drvt makes flat slice, too wet. Hot pressing (after heating): To scratch seeds by two slices of wood, if shell and kernel could be splitted, water content is adequate. If kernel becomes power, it is too dry; in the case that shell and can be splitted, it is too wet.

2. Cakes thickness reflects the pressure inside the chamber. Thicker cake indicates lower pressure inside the chamber, thinner cake-higher pressure inside. If raw material has less oil content, chamber pressure should be higher, cake will be thinner, round plates need to be tightenedt In the case of high oil content material, pressure in the chamber should be lower, then circular plates need to be loosened, resulting in thicker cake. Recommended thickness of cakes will be.

- Bean: 1.1 — I .5mm for the first pressing ; 0, 5 -1 mm for the second pressing.

- Cotton seeds : only one pressing , 1—2mm.

- Ground nut kernel ; Normally cold pressing for 2—3 times , 1—2mm

- Important note: cakes thickness should be as according to different factors to achieve highest oil output rate.

Quick Message

PROCUTS

- small oil press

- YZS-100 oil press

- YZS-120 oil press

- YZS-30 automatic oil press

- YZS-70 automatic oil press

- YZS-95A automatic oil press

- YZS-120A automatic oil press

- YZS-130A automatic oil press

- ZX-95A oil press

- ZX-130 oil press

- YZS-68 oil press

- YZS-80A automatic oil press

- YZS-80 oil press

- YZS-95 oil press

- YZS-100A automatic oil press

- YZS-130 oil press

- big oil press

- plate filter press

- manual oil press

- soybean extruder

Recommend Products

Blog

- What's the Main Filtering Method in Edible Oil Processing Plant?

- difference between small oil press and big oil press

- Mustard Oil Mill Machinery

- LYZX24-1 Oil Presses

- Oil Pressing Plant

- Palm Kernel Oil Press Machine

- Walnut Oil Press Machine

- screw oil expeller with big capacity

- large oil press

- Peanut Oil Mill