Vegetable Oil Refining Manufacturer,Palm Oil Refining Companies,Oil Press

The oil refining system consists of rendering kettle, decolorizer-dryer, deodorizer, soapstock kettle, crystallizer, filter machine, heat conduction boiler, vacuum system, refrigerating unit etc. The crude oil passed the process of degumming, deaeration, decolorizing, de-waxing, and deodorizing, to gain various of class oil.

There are three kinds of forms as follows: batch refining(below 50T/D), semi-continuous refining(20~80T/D), continuous refining(30T/D). Can be selected in accordance with request.

Our line of edible oil refining process systems are specially designed to produce an odorless, bland, and stable oil with the appropriate color for a wide variety of cooking and baking applications. From low-cost production of bulk commodity salad and cooking oils to development of the most sophisticated designer-type oils and fats system. We provide the oil expellers/oil press with the latest technology and lowest operation costs.

Process flow For Oil Refining

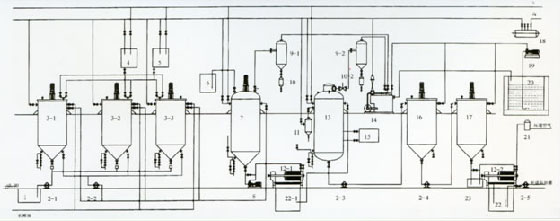

1. Batch Oil Refining

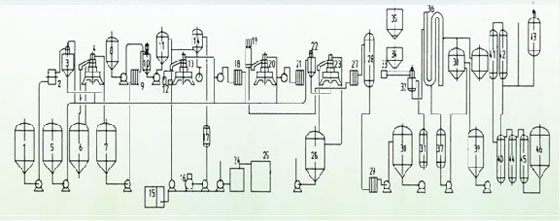

2.Continuous Oil Refining

Vegetable Oil Refining Technology

We classify it into Physical Refining & Chemical Refining according to different technology. Features of these two technologies:

Physical Refining

Remove gums in oil with special degumming method. FFA in oil is removed by steam. Features:

High oil refining rate, less oil loss

No waste water discharged;

More FFA distilled out;

Especially suitable for oils of high acid value, and low gum content;

Chemical Refining

Neutralize FFA in the oil with alkali. The gum and soap produced are centrifuges. Features:

Less requirements to crude oils;

The finished oil is more consistent in quality;

Less bleaching earth used compared with physical refining;

Best oil refining in Gemco, excellent quality, favorite price, considerate service!

PROCUTS

- small oil press

- YZS-100 oil press

- YZS-120 oil press

- YZS-30 automatic oil press

- YZS-70 automatic oil press

- YZS-95A automatic oil press

- YZS-120A automatic oil press

- YZS-130A automatic oil press

- ZX-95A oil press

- ZX-130 oil press

- YZS-68 oil press

- YZS-80A automatic oil press

- YZS-80 oil press

- YZS-95 oil press

- YZS-100A automatic oil press

- YZS-130 oil press

- big oil press

- plate filter press

- manual oil press

- soybean extruder

- What's the Main Filtering Method in Edible Oil Processing Plant?

- difference between small oil press and big oil press

- Mustard Oil Mill Machinery

- LYZX24-1 Oil Presses

- Oil Pressing Plant

- Palm Kernel Oil Press Machine

- Walnut Oil Press Machine

- screw oil expeller with big capacity

- large oil press

- Peanut Oil Mill